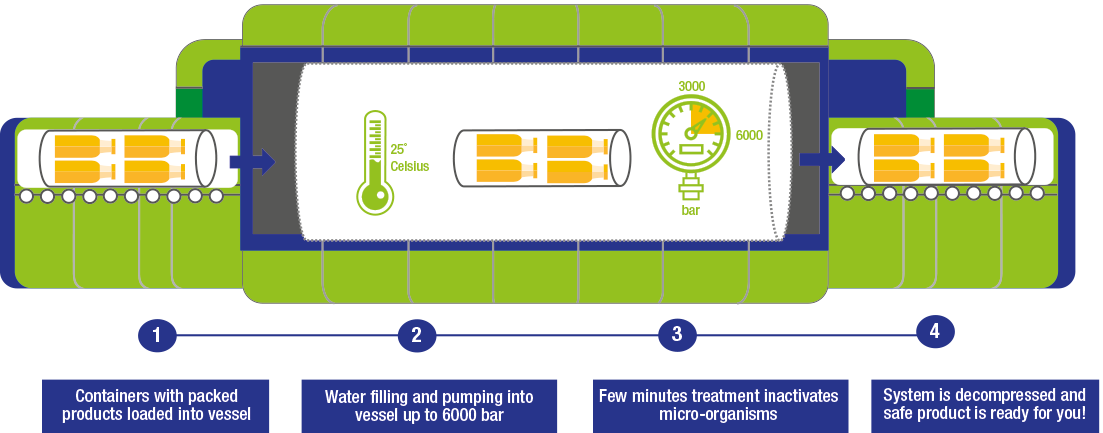

Here Are Our Four Guarantees

100% More Shelf Life

HPP reassures South African brands of a longer product shelf life achieved through an all-natural process. The longer your products last, the further they can be distributed and sold.

100% Guaranteed Food Safety

We don’t compromise on food safety as our innovative preservation methods helps ensure the best product quality for your brand. Protect your customers through a preservation process that you know is reliable, safe and pure.

100% Guaranteed Taste, Colour and Flavour

Our innovative high-pressure technology guarantees the same great taste for your products, with the added benefit of a long-lasting freshness sealed in with our convenient safe packaging. Take the next step to becoming part of the better-for-you product revolution.

100% Biological, No Additives

Our powerful HPP process utilises 60,000 pounds per square inch of water pressure to kill bacteria in a natural way that does not alter the taste, freshness or texture of food. HPP kills pathogens in a tried and tested method.